Feb 21, 2026 | Uncategorized

Key points ASTM, ASME, and EN standards define material properties, inspection requirements, and documentation for industrial tubing. In regulated sectors such as power, petrochemical, and marine, compliance with the correct standard determines project approval and...

Feb 15, 2026 | Uncategorized

Key points In critical industrial projects, choosing a specialized trading partner is a risk management decision, not a commercial shortcut. A technically competent supply partner understands standards, inspection requirements, and manufacturing constraints, ensuring...

Jan 31, 2026 | Uncategorized

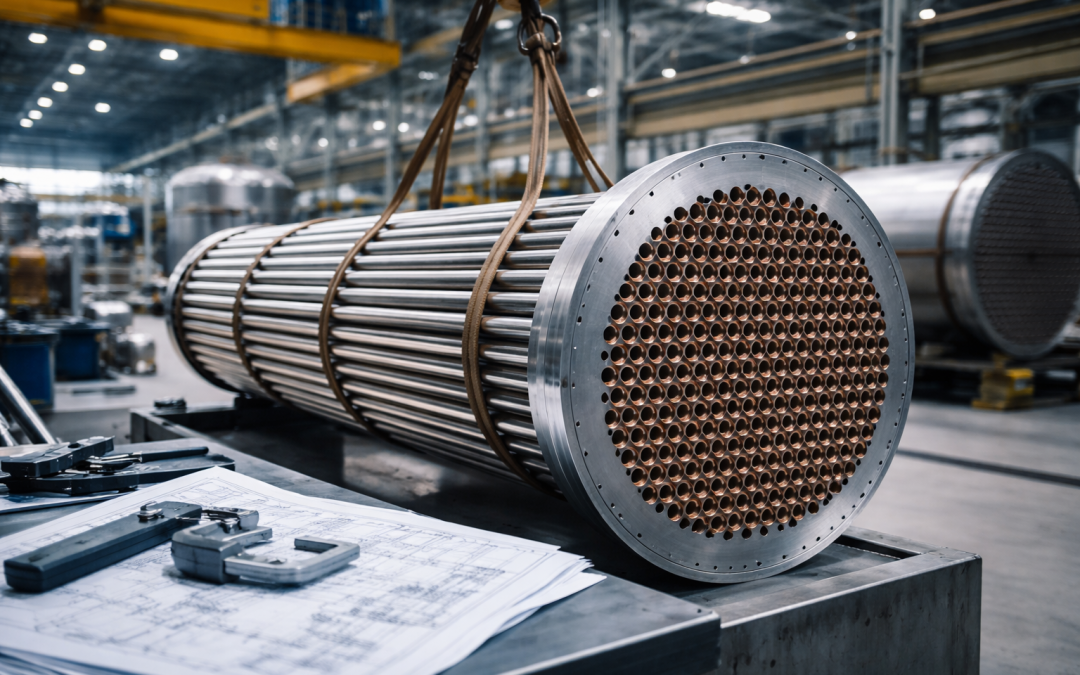

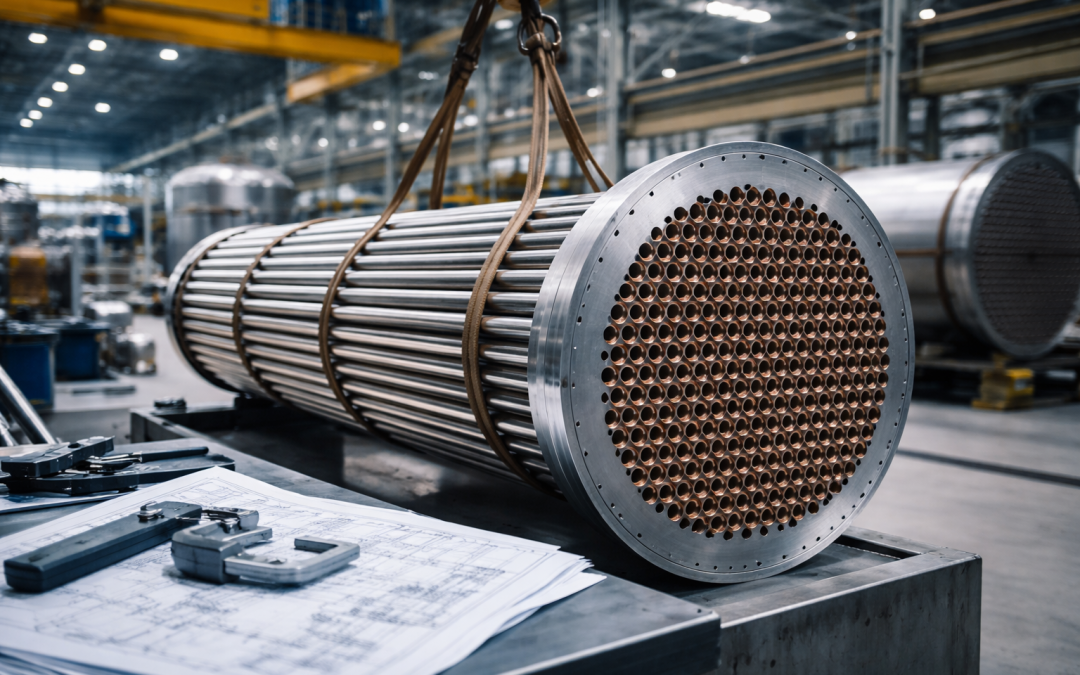

Key points Heat exchanger tubes often fail inspection due to specification gaps, testing and acceptance mismatches, or incomplete traceability documentation. Preventing rework starts before manufacturing with clear requirements, agreed inspection methods, and...

Jan 17, 2026 | Uncategorized

Key points Heat exchanger tube failures are most commonly caused by corrosion, erosion, and incorrect material selection. Understanding failure modes such as dezincification, galvanic corrosion, and wall thinning helps engineers and buyers choose the right tube...

Nov 30, 2025 | Uncategorized

Key points Copper prices remain elevated due to tight supply, mine disruptions, smelter bottlenecks, and geopolitically distorted trade flows. Demand continues to accelerate, driven by the energy transition, data-center expansion, and strong consumption from the US...

Nov 16, 2025 | Uncategorized

Key points Selecting copper alloys (CuNi 90/10, 70/30), nickel-based alloys, finned tubes, and tube sheets requires careful attention to ASTM/ASME standards, service environment (marine, chemical, HVAC), fin configuration (L/G/embedded), and machining tolerances. This...