CASE STUDY: Key Insights

-

Admiralty Industries delivers engineered heat exchanger components aligned with the tight timelines and risk profile of refinery turnarounds.

-

In house control of materials, overlays, and quality verification enables reliable execution of complex multilayer solutions.

-

A procurement focused approach, combining technical rigor with schedule discipline, reduces installation risk and unplanned downtime for refinery operators.

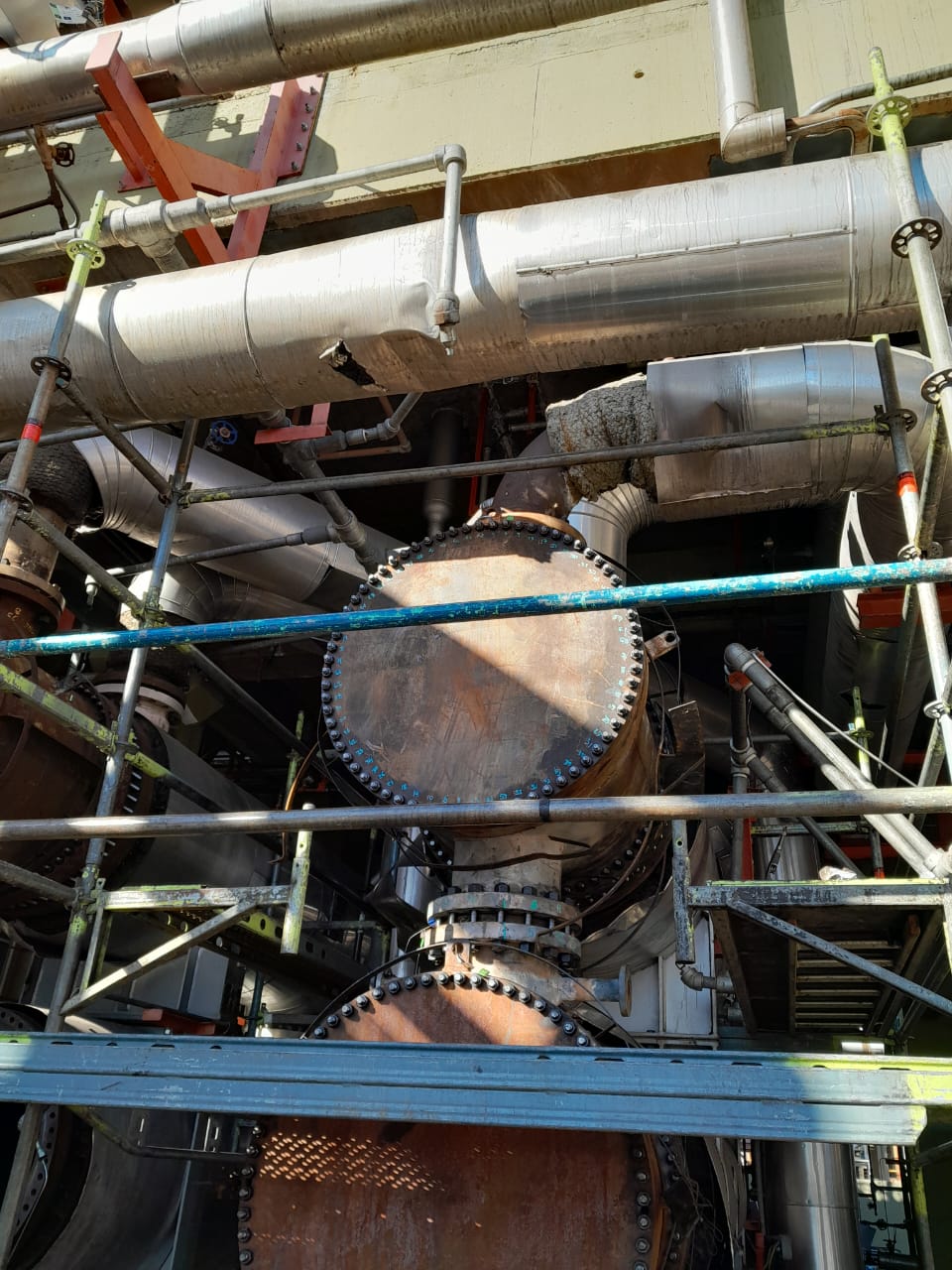

Client and Project Overview

Client: YPF S.A., high conversion refining complex

End User: YPF Luján de Cuyo Refinery

Industry: Oil and Gas, Refining

Location: Mendoza, Argentina

Project Scope: Supply of a multilayer closure disk for a shell and tube heat exchanger channel head

Delivery Window: Scheduled refinery turnaround

Admiralty Industries was engaged to manufacture and deliver a critical closure component for a refinery heat exchanger operating in demanding service conditions. The project was executed within the strict time constraints of a planned turnaround, where delays or rework would have had direct operational and financial impact.

Industry Context and Operational Challenge

Shell and tube heat exchangers in refinery service are exposed to high temperatures, aggressive process fluids, and cyclic operating conditions. Components such as channel head closure disks must combine mechanical strength with reliable corrosion resistance while maintaining full dimensional and metallurgical integrity.

In this case, the existing closure disk required replacement during a scheduled turnaround. The solution had to meet stringent performance requirements while being delivered within a limited and non extendable maintenance window.

Technical Requirements and Constraints

The project presented several critical constraints:

-

Delivery within a restricted turnaround schedule

-

High mechanical strength to withstand operating pressure and temperature

-

Corrosion resistance suitable for refinery service

-

Controlled metallurgical transition between dissimilar materials

-

Guaranteed net overlay thickness to avoid on site rework

-

Full dimensional control and traceability

Failure to meet any of these requirements would have increased installation risk or extended downtime.

Admiralty Industries’ Solution

Admiralty Industries engineered and supplied a multilayer closure disk designed to balance structural performance with corrosion protection. The solution combined a high strength Cr Mo steel base with stainless steel overlays applied in controlled layers.

This multilayer configuration ensured compatibility with the existing heat exchanger design while providing the required resistance on the process exposed surfaces.

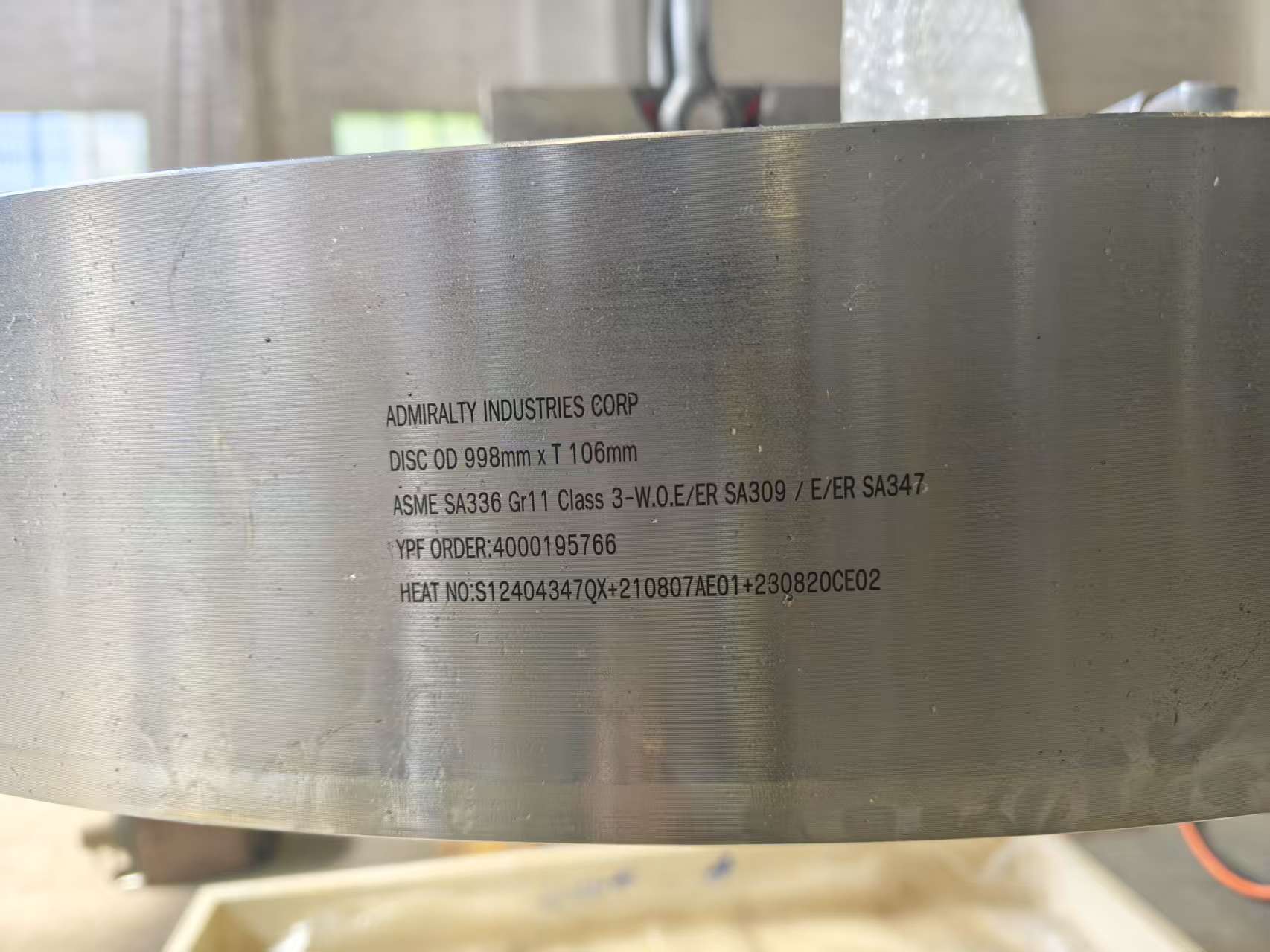

Materials, Standards, and Specifications

The delivered component was manufactured to the following specifications:

-

Base Material: ASME SA336 Gr11 Class 3 Cr Mo steel, 96 mm thickness

-

Intermediate Overlay: ASME SA309 stainless steel buffer layer, 5 mm thickness

-

Final Overlay: ASME SA347 stainless steel corrosion resistant layer, 5 mm thickness

-

Disk Diameter: 998 mm

The intermediate SA309 layer was used to ensure a controlled metallurgical transition between the Cr Mo substrate and the final stainless steel overlay, reducing the risk of cracking or dilution issues.

Manufacturing and Implementation

The manufacturing process followed a tightly controlled sequence aligned with turnaround deadlines:

1. Forging and machining of the SA336 Gr11 base disk

2. Application of the SA309 buffer overlay with intermediate inspection

3. Application of the SA347 final overlay with verification of net thickness

4. Final machining, cleaning, documentation, and preparation for shipment

Quality control included dimensional checks, overlay thickness verification, and full documentation to support traceability and installation readiness.

Outcome and Key Results

The closure disk was delivered within the scheduled turnaround window and installed without the need for any on site rework. The component met all dimensional and metallurgical requirements and was successfully commissioned as part of the heat exchanger restart.

Key results included:

-

Zero rework during installation

-

On time delivery aligned with turnaround planning

-

Reduced corrosion risk in critical service

-

Restored equipment availability without startup delays

| KPI | Result |

|---|---|

| Delivery schedule | Delivered within turnaround |

| Installation outcome | Installed with zero rework |

| Overlay tolerances | 100% compliant |

| Equipment availability | Restored to service |

Client Feedback

“The disk arrived on time, installed perfectly, and the internal team was pleased with the purchase management.”

Why This Matters for Similar Projects

This project highlights the importance of combining material selection, overlay engineering, and manufacturing discipline when supplying critical heat exchanger components for refinery turnarounds. Multilayer solutions can extend equipment life and reduce operational risk when executed with controlled metallurgy and guaranteed net thickness.

For refineries operating legacy equipment under modern performance expectations, careful supplier coordination and technical execution are decisive factors in successful turnaround outcomes.